Lightning has become more and more ferocious nowadays in Malaysia as the climate is changing over year throughout the decade. The number of accidents caused by lightning strikes are increasing exponentially every year. Thus, Lightning Protection System is becoming more important protective measure to protect the occurrence of lightning strikes and thunderstorm from causing further damages to our property and human lives.

Lightning Protection System can be categories into two types which are:

Ø External/Structural Lightning Protection System

Ø Surge Protection System

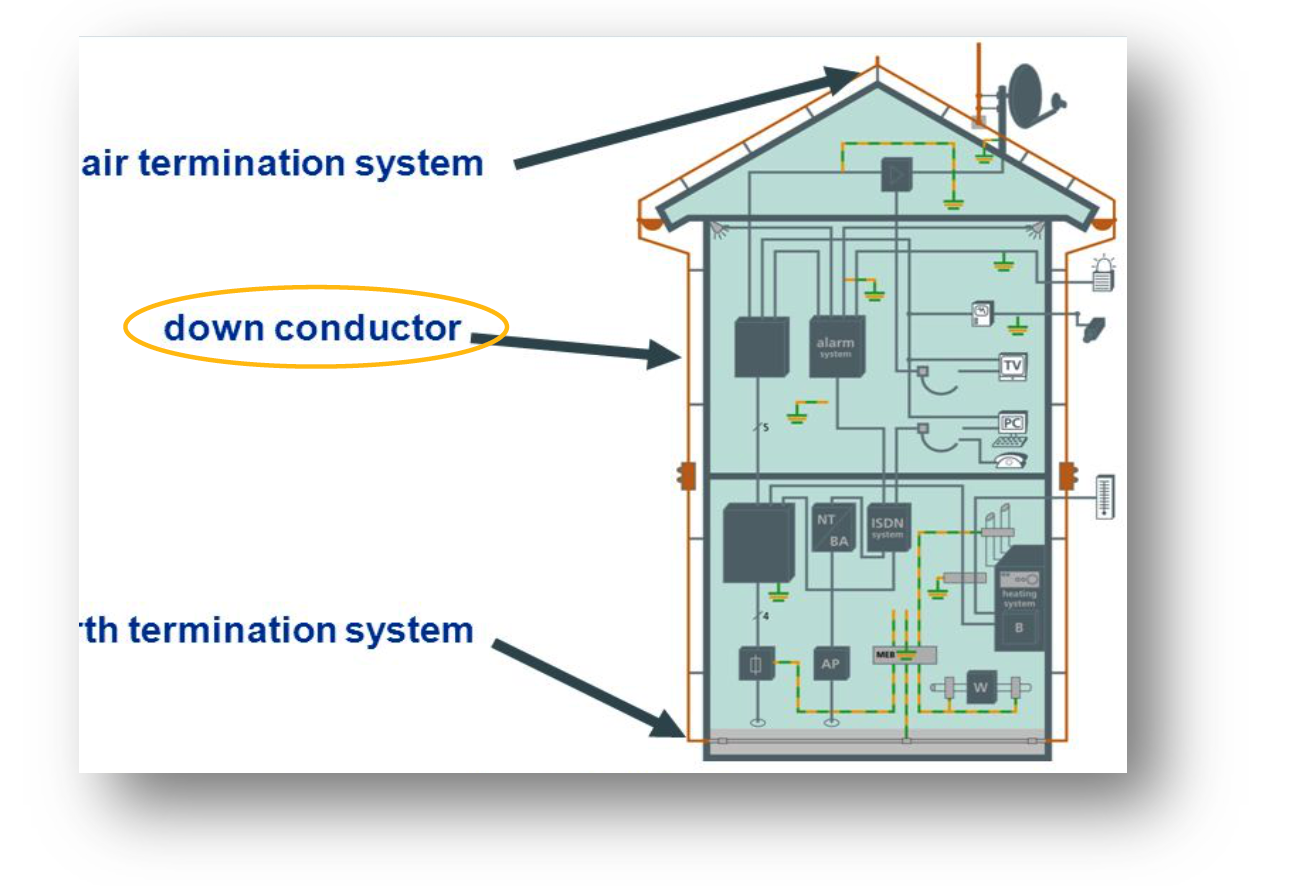

As per our understanding, direct lightning strike is so strong and powerful that it can penetrate the concrete or steel structure of any buildings. This will lead to the debris fractured from any building fall to the ground. Human lives will be in danger when they passed through the premises. External/Structural lightning protection system is a system to protect the external structure and life beings from direct lightning strikes. It can be further separate into three major systems naming:

v Air Termination System

v Down Conductor System

v Earth Termination System

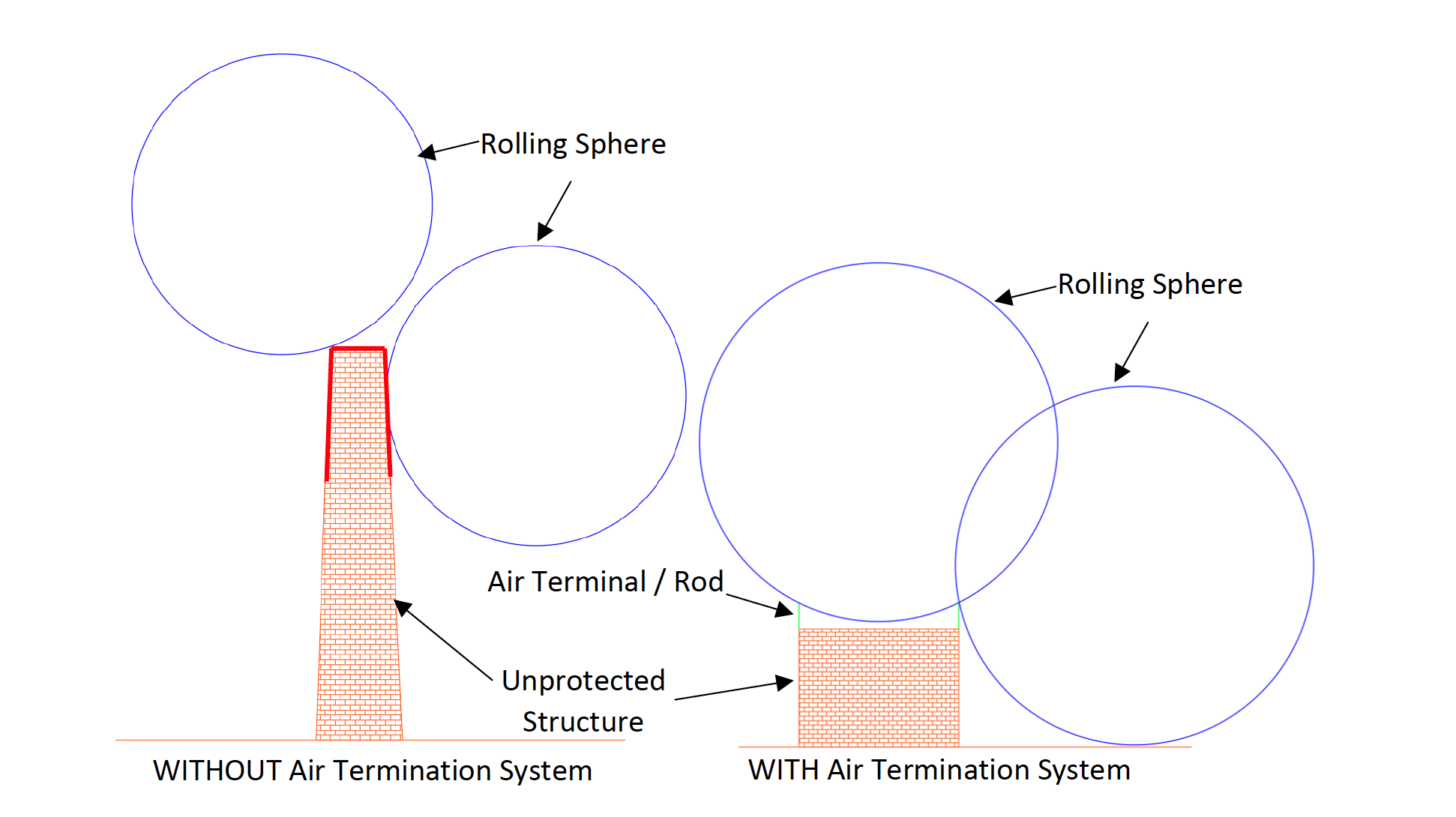

Air termination system is defined as a part of external lightning protection system consist of metal rod, mesh conductors, catenary wire intended to intercept with lightning flashes (direct lighting Strike) in IEC 62305-part 3 at year 2011.

According to the standard, air termination system shall be design using rolling sphere method, protective angle method and mesh method in accordance to IEC 62305 standard code of practice.

Rolling Sphere Method

ü Rolling Sphere Method is suitable to be implemented on any kind of structure regardless of the height and with complex shape.

ü Air termination system shall be implemented at the areas which touch by the sphere.

ü It shall be implemented in accordance to lightning protection level (LPL)

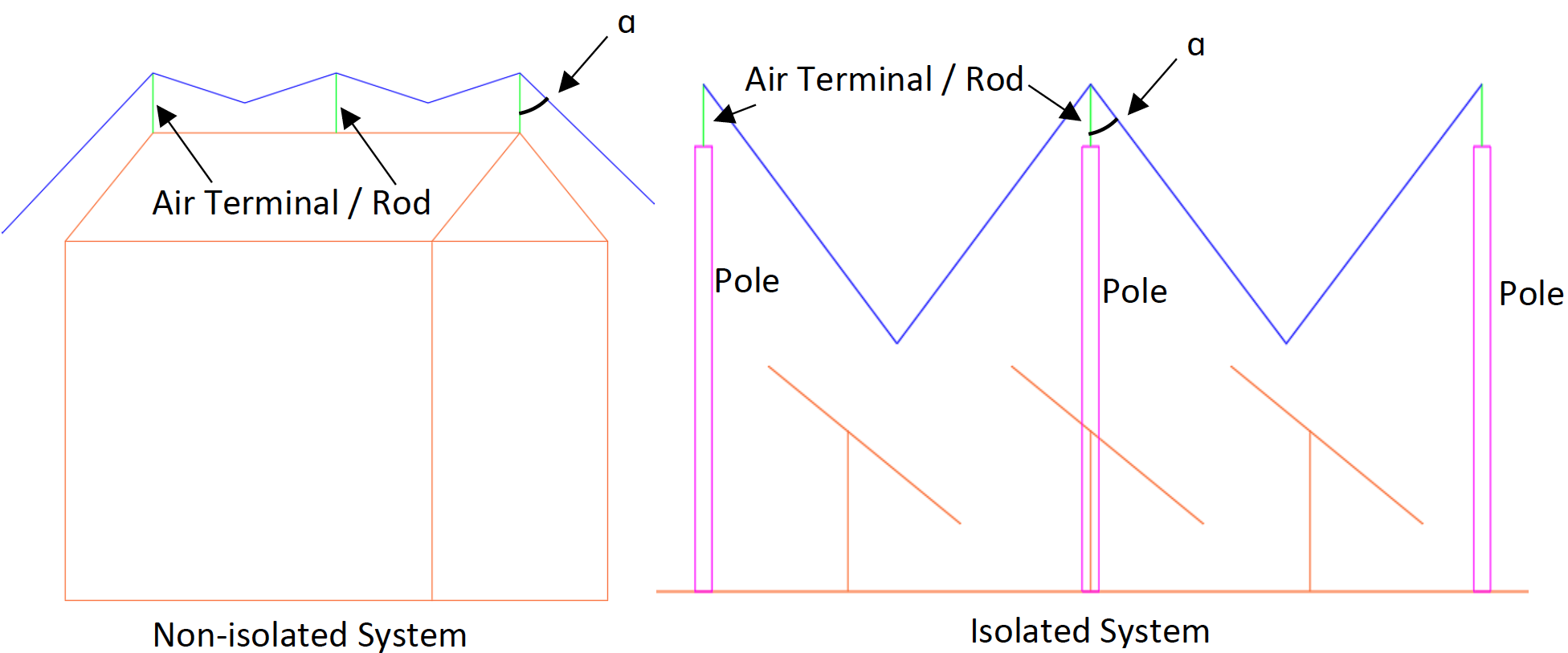

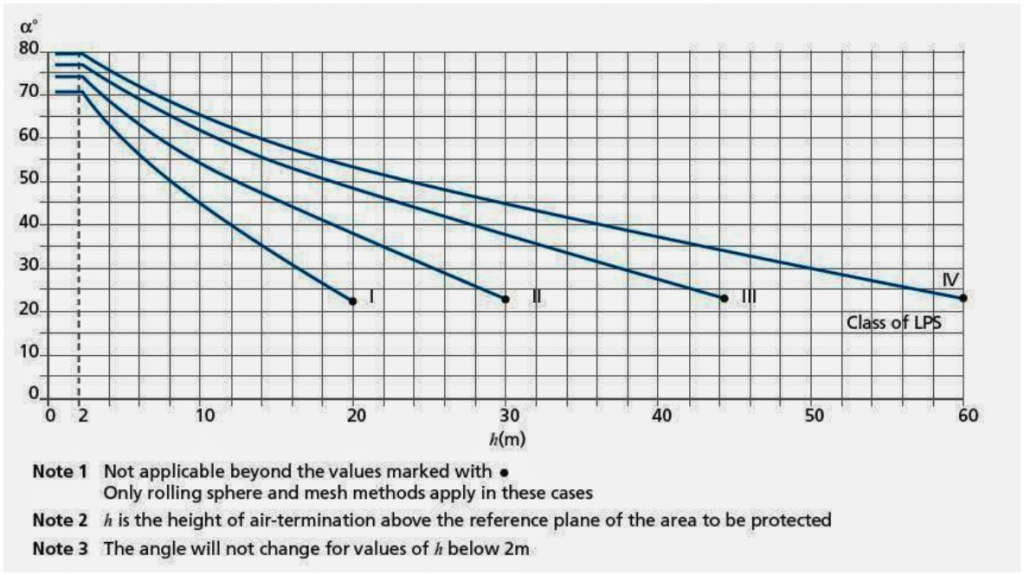

Protective Angle Method

ü Protective Angle Method is suitable to be implemented for building of simple structure and less than 60m in height.

ü It can be used to design isolated lightning protection system and non-isolated lightning protection system in accordance to IEC-62305 part 3.

ü The protective angle,α shall be determined in conjunction with the reference plane in accordance to IEC-62305-part 3 standard code of practices.

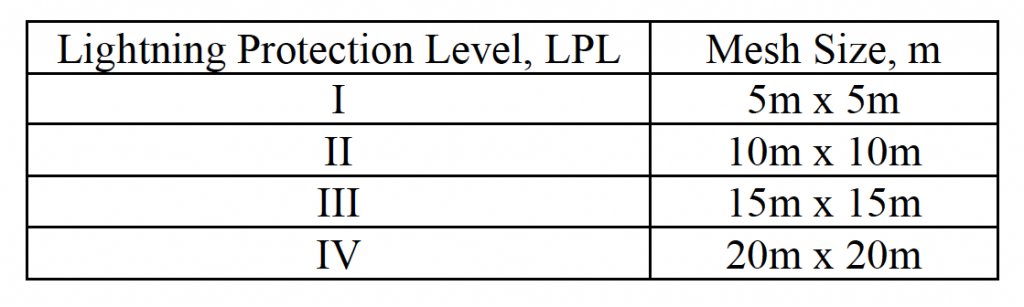

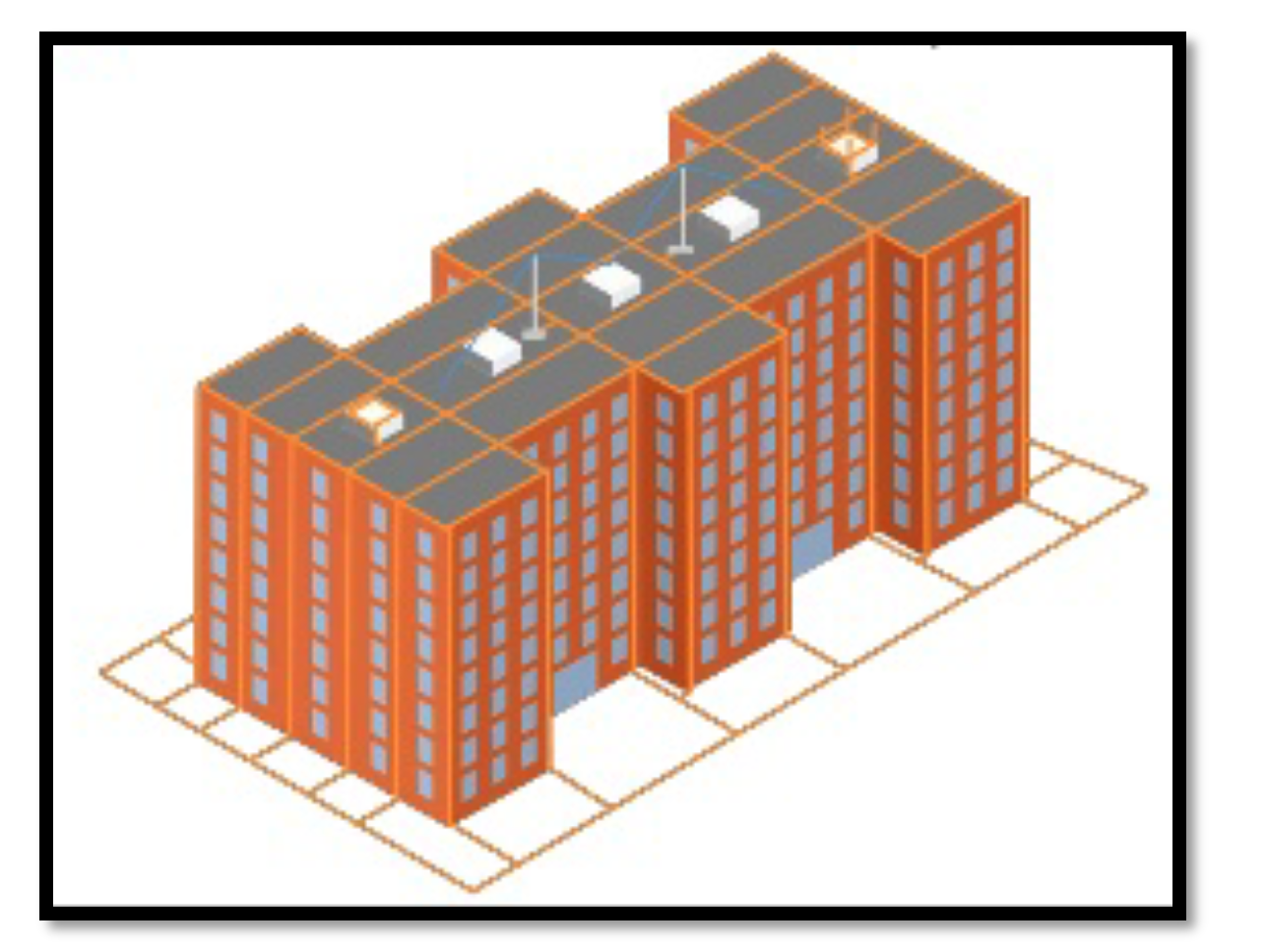

Mesh Method

ü Mesh Method is suitable to be implemented on structure with a flat surface on top of the buildings.

ü The mesh size shall be designed in accordance with IEC 62305-3.

ü The mesh size can be used together with air terminals / rods to enhance the protections.

Air rod/terminal is a length of rod with different length that installed at the roof top level to act as a charge tip that will accumulate charges at the tips to increase the chance of striking by lightning compare to the other surface in the event of lightning strike occurrence. Copper is one of the best metals to be selected for its conductivity and other characteristics. Other than copper, there are other material that can be used to be air terminal for example aluminum and steel.

Preventation Engineering provide expert and professional services in assisting our customer on designing and proposing the leanest concept of air termination system in accordance with IEC 62305-3 standard code of practices.

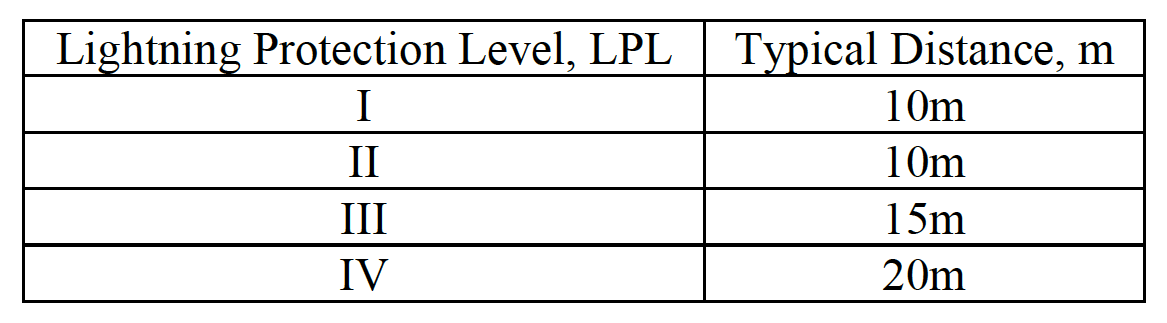

Down conductor system is defined as a part of external lightning protection system intended to conduct lightning current between the air-termination system and the earth-termination system in IEC 62305-part 3 at year 2011. For isolated LPS, at least ONE (1) down-conductor is need for each mast where the air termination is of a separated mast. One the other hand, the number of down-conductors shall not be less than TWO (2) and should be distributed around the perimeters of the structure to be protected for non-isolated LPS. The separation distance between down conductors is being determined in Table 4 of IEC 62305 part 3 which stated below.

Earth Termination system is defined as part of External LPS intended to conduct and disperse lightning current into the earth. It is a very important system as most of the lightning current to the ground. There are two main type of earthing arrangement specified in the standard.

ü Consists of vertical and horizontal earth electrodes drive into the ground.

ü Each earth electrode will be connected firmly with the down conductor using test clamp.

ü Normally installed outside the structure.

ü Suitable for low rise building.

ü The minimum length of each driven earth electrode is 2.5m

ü Ring Conductor forming a perimeter surround the structure.

ü Normally buried in depth and join to all down conductors using test clamp.

ü Suitable for high rise building, rocky ground and structure with sensitive equipment.

ü The perimeter should be in contact with the soil for more than 80% for its total length.

ü If the required resistance cannot be achieved, vertical earthing electrodes shall be implemented to the mesh.

ü The alternative of this method is foundation earth electrode.